News Updates

09

2022-06

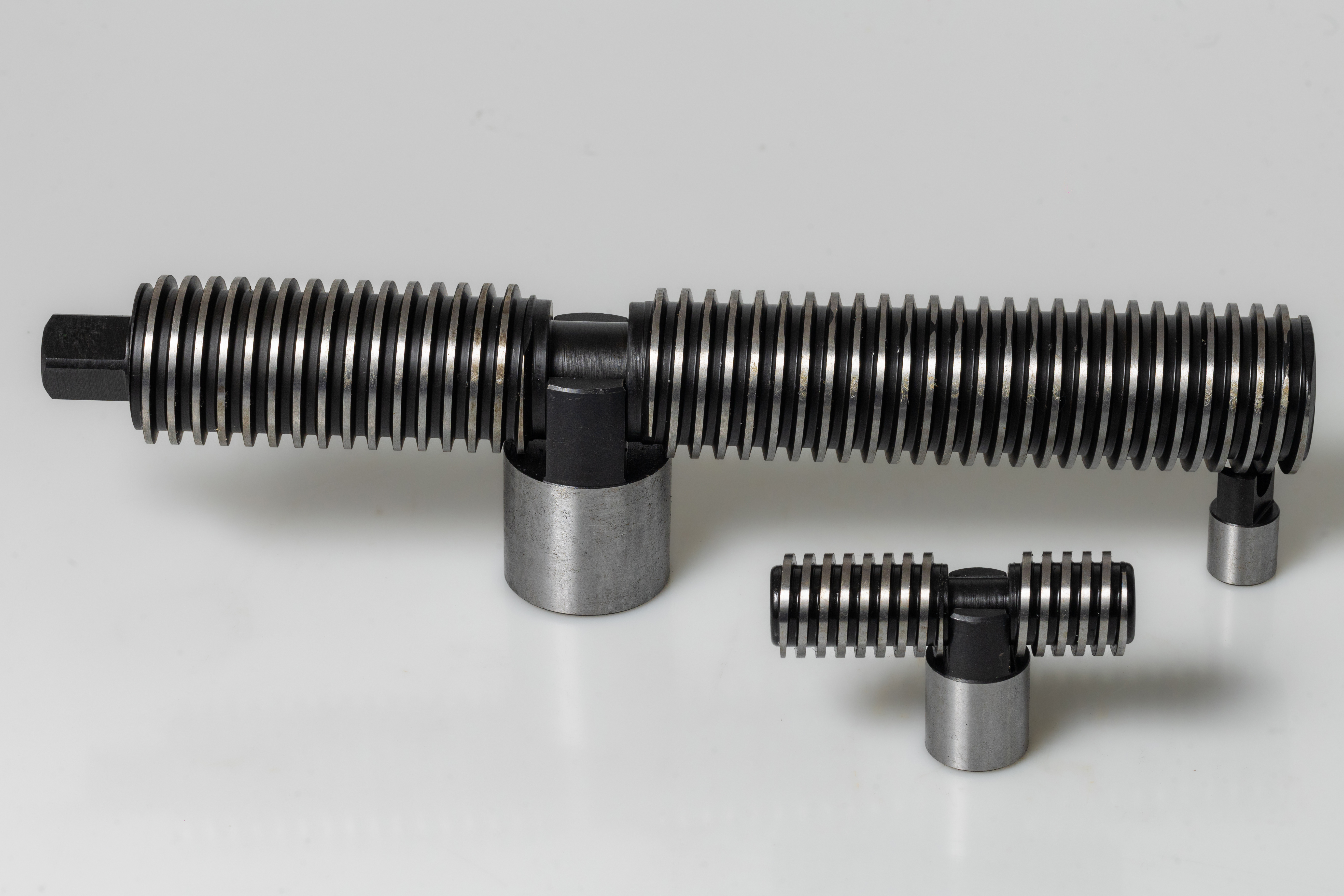

The mechanical arm equipment lead screw production factory promises to keep promises "Sutong Machinery"

The faults caused by ball screws are diverse and have no fixed pattern. Some faults are gradual and require a development process, which becomes increasingly severe with the increase of usage time; Sometimes it is a sudden malfunction, usually without obvious signs, but it occurs suddenly. This type of malfunction is caused by various unfavorable factors and the combined action of the outside world. So determining the true cause of the malfunction through correct detection is a prerequisite for fast and accurate maintenance.

View More

Special screw information recommendation: Sutong Machinery

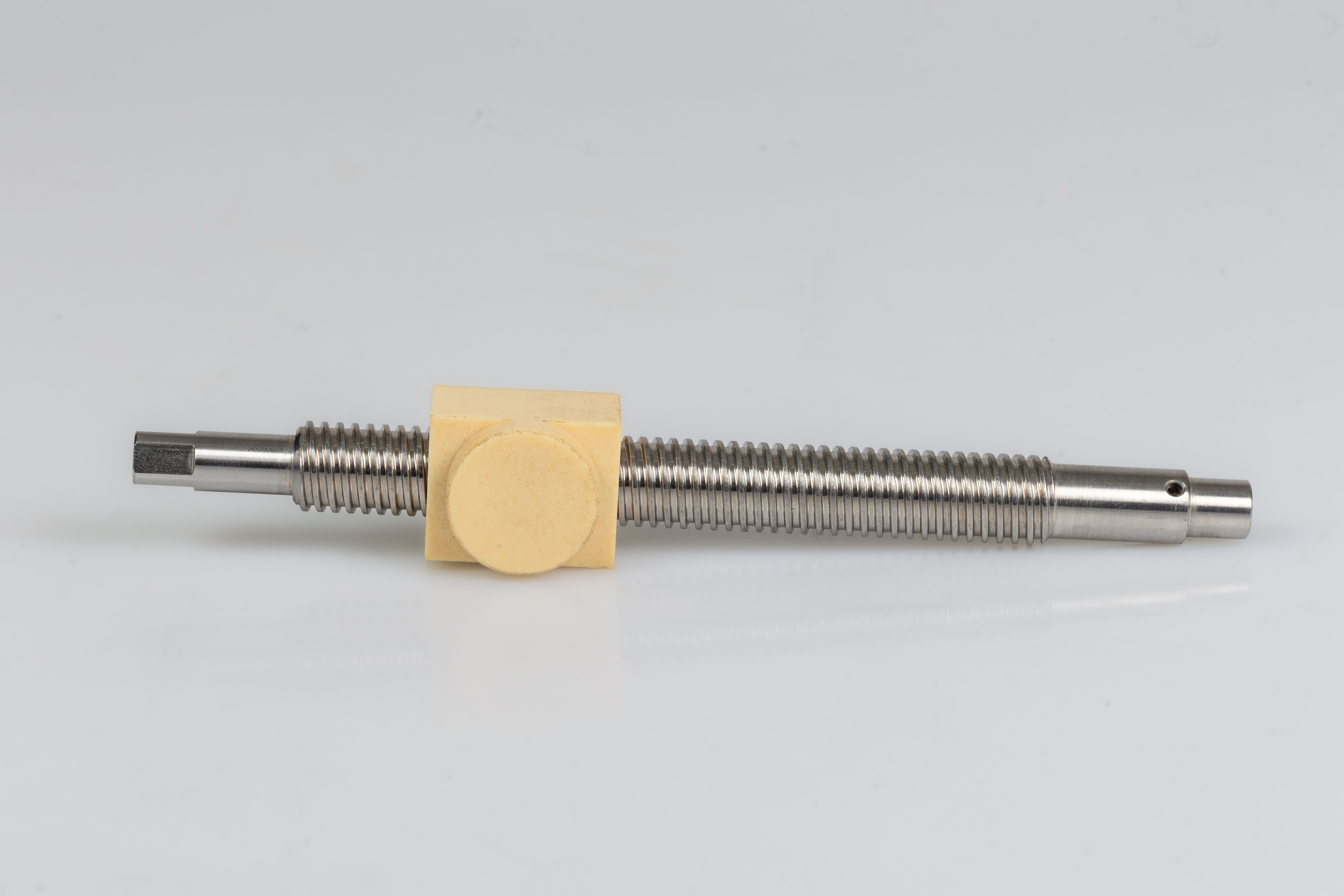

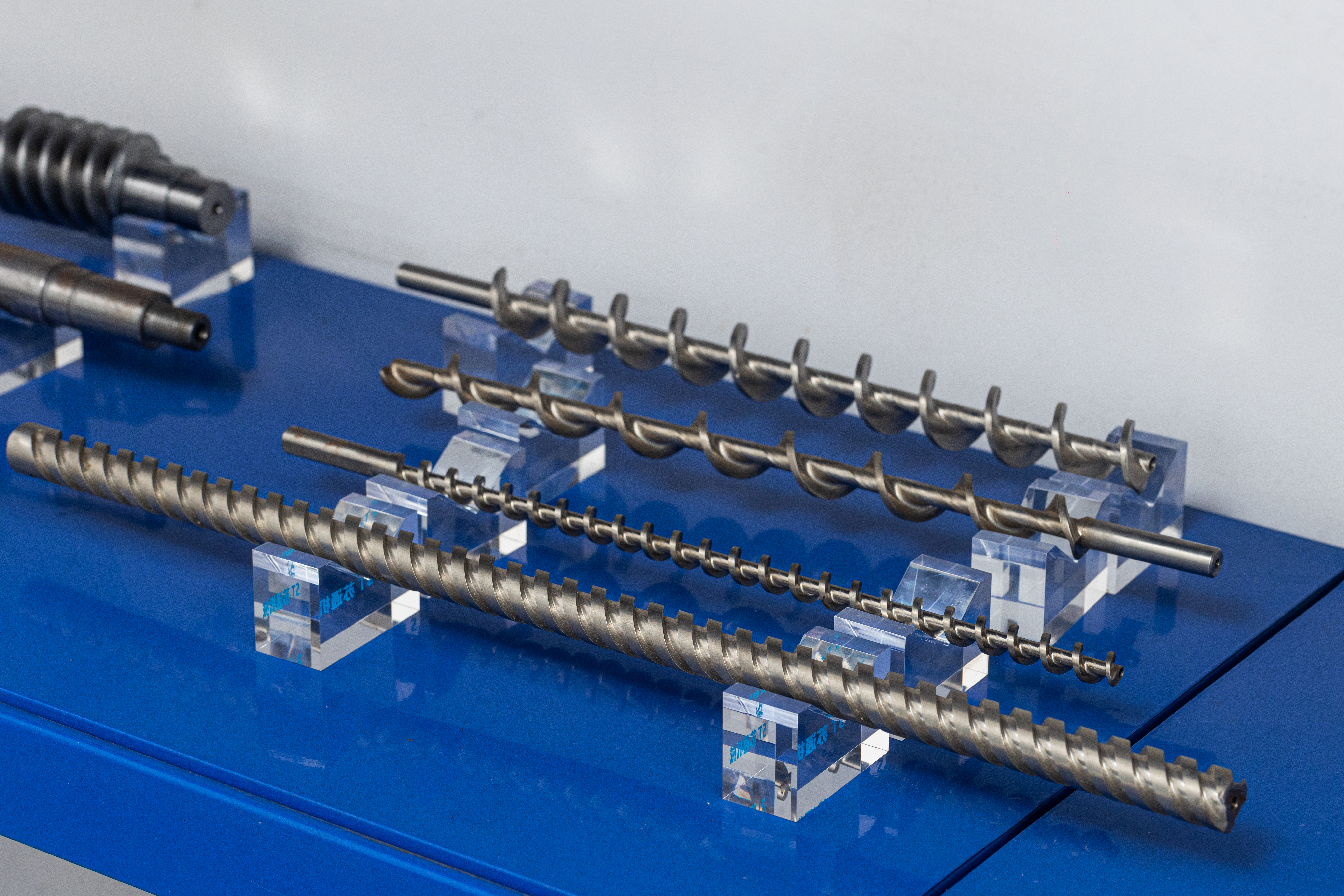

There are some differences in the application of ball screws and trapezoidal screws. The application systems of original equipment manufacturers often require products that are "exactly right", and trapezoidal screws are often the right choice. The trapezoidal screw product is easy to adjust based on specific applications to achieve expected performance while keeping costs at a low level. In some cases, life testing may be required during the design phase, but for original equipment manufacturers, conducting such additional work in the early stages can help reduce product costs. The ball screw can operate continuously, withstand much higher loads, and achieve faster speeds, which is worth the additional cost. For end users of Zui, ball screws have good predictability, making them the best choice for ensuring fast integration and reliability. For example, factory automation systems heavily rely on ball screw technology. Of course, many original equipment manufacturers also require ball screws for their application systems, such as in the machine tool industry.

15

2022-08

njection molding machine screw factory welcome to call "Duotu"

Maintenance precautions for screws: 1. Do not start the machine when the screw has not reached the preset temperature. 2. To prevent metal fragments and debris from falling into the hopper, if processing recycled materials, a magnetic hopper needs to be added to prevent iron filings from entering the barrel. 3. When using anti saliva, it is important to ensure that the plastic inside the barrel is completely melted to prevent damage to the transmission system components when the screw moves back. 4. When using new plastic, the remaining material of the screw should be cleaned thoroughly. 5. When the temperature of the molten plastic is normal but black spots or discoloration are continuously observed, the rubber screw should be checked. During processing, try to make the material plasticize evenly and avoid mixing metal foreign objects into the material to reduce the torque force of the screw rotation.

16

2022-08

Self locking screw service is thoughtful for "Sutong Machinery"

Usually, during the installation process, simply use a wrench to move clockwise. When disassembling, it can be removed by turning it counterclockwise. Different specifications and lengths of screws can be selected based on different contours, groove widths, and installation requirements. Screw can be widely used in some industrial production and mechanical processing production. In industrial and mining enterprises, screws are often seen. Even if it is small, its effect is infinite. It is widely used in our lives. There are many differences in the material of screws, and correspondingly, screws of different materials are used in different scenes and positions.

28

2022-08

Contact Wuxi Sutong Machinery Co., Ltd. for inquiries regarding the processing of threaded rods in robotic arm equipment

The plastic mechanical reciprocating single screw system is equipped with a two-stage granulation unit, which uses an equally spaced and deep single screw extruder to transport the melt, complete plasticization and longitudinal mixing, and establish a stable extrusion pressure due to its low speed. After the outer cement mortar has finally set, inject polyurethane foam adhesive into the bolt hole from the inside. The hole can be filled or 20-30mm can be reserved on the outside for sealing with cement mortar after the foam adhesive dries and hardens. Therefore, the shearing is lower, avoiding the main shearing heat of the material, and the temperature control is better.

31

2022-08